Boost Your Workflow Using Automated Gluing Solutions

Wiki Article

The Ultimate Guide to Woodworking Equipment: Boost Your Projects With Advanced Equipment

The domain of woodworking machinery uses a vast array of devices developed to improve both precision and creativity. From table saws to CNC machines, each item of tools provides distinct benefits. Understanding the necessary functions and precaution can significantly impact the quality of a project. With the ideal knowledge, woodworkers can make informed choices that raise their workmanship. What details devices and techniques can change an average task into an amazing one?Necessary Woodworking Equipment for Beginners

When starting on a woodworking journey, novices should prioritize necessary machinery that simplifies the crafting process. A table saw attracts attention as a fundamental device, making it possible for accurate cuts for numerous jobs. Its adaptability enables crosscutting and tearing, crucial for creating specific elements.One more essential device is the miter saw, which facilitates tilted cuts for frameworks and trim job. This tool boosts precision and efficiency, enabling for clean joints in tasks.

In addition, a drill press is useful for guaranteeing regular hole positioning and deepness, which is vital for assembly and attachment.

Finally, a planer is important for attaining smooth, also surfaces on harsh lumber, enhancing the final appearance of projects.

Advanced Equipment for Experienced Woodworkers

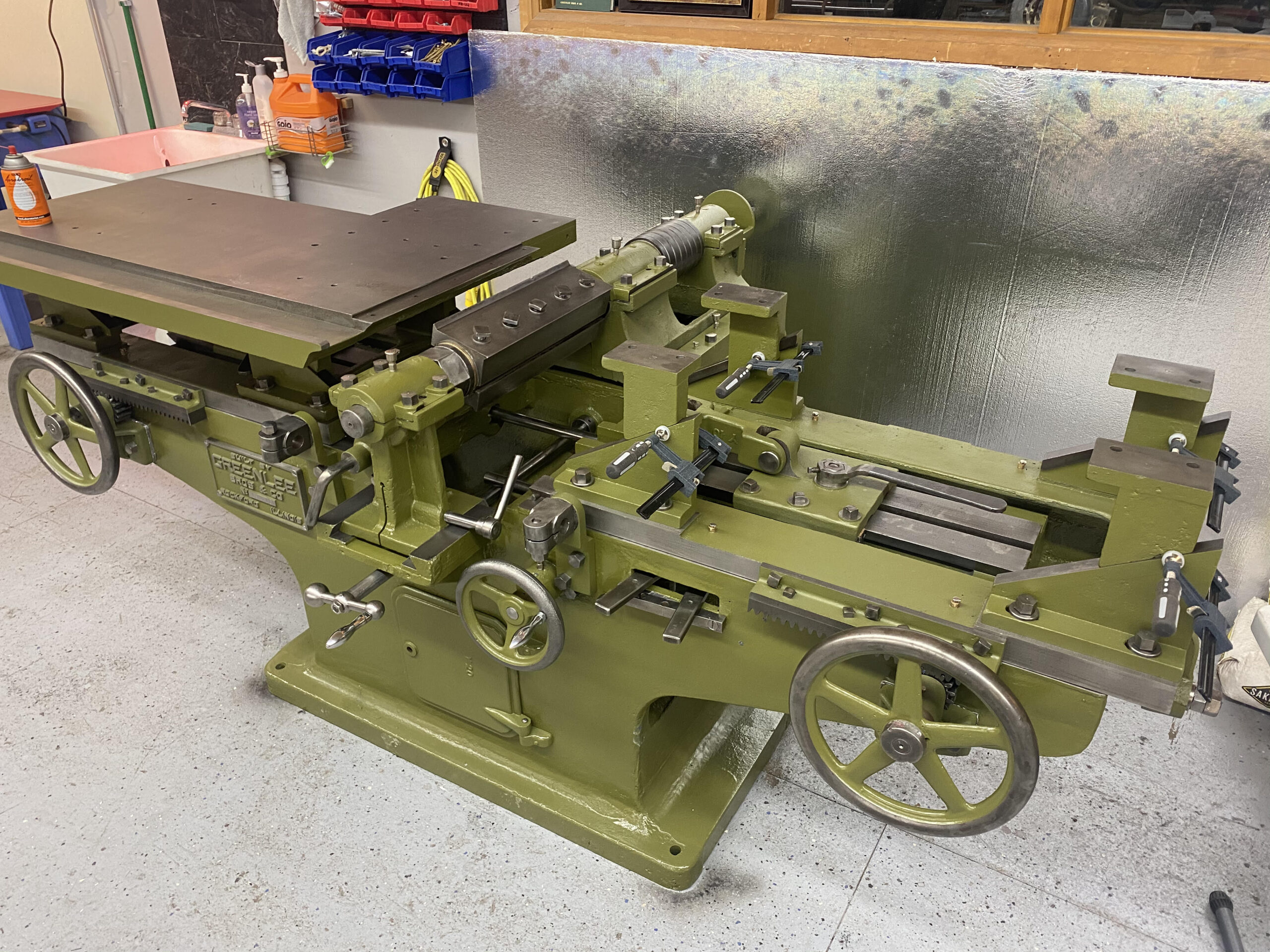

Experienced woodworkers typically take advantage of a selection of advanced tools that improve their craftsmanship and increase their abilities. Amongst these devices, precision table saws play a necessary role, allowing exact cuts and complicated angles. Furthermore, routers geared up with different little bits enable elaborate styles and attractive edges, boosting the quality of completed jobs.Jointers and planers are critical for accomplishing smooth, tight joints and flat surface areas, ensuring that pieces meshed flawlessly. Lumber Stacker. Bandsaws offer adaptability for both straight and rounded cuts, making them vital for creative layouts

Dust collection systems are likewise crucial, advertising and keeping a clean office safety and security. Moreover, CNC makers supply automation, allowing woodworkers to carry out intricate layouts with remarkable precision and repeatability. These advanced tools not just enhance efficiency yet also empower knowledgeable woodworkers to push the limits of their creative thinking, transforming concepts into stunning, high-quality items.

Key Features to Seek in Woodworking Equipment

Picking the right woodworking devices calls for cautious analysis of essential features that improve performance and efficiency. Power and electric motor capability are necessary, as they identify the efficiency and performance of tools. Additionally, accuracy design is essential for precise cuts and surfaces, making functions like flexible fences and tweak handles considerable.Sturdiness must not be forgotten; equipment made from top notch products can hold up against extensive use and offer lasting efficiency. Transportability is an additional feature to think about, specifically for those with minimal workspace, as compact designs can improve usability.

Functional designs play a crucial role in user convenience, reducing fatigue during extended use. Ease of maintenance and schedule of substitute components can significantly affect the lasting functionality of the equipment. Compatibility with accessories and accessories can increase the flexibility of the devices, making it a more valuable financial investment for any woodworking task.

Safety Tips When Using Woodworking Equipment

Woodworking can be a fulfilling and creative pursuit, it is critical to prioritize safety and security when operating machinery - Woodworking Machinery Products. First and primary, individuals must wear ideal individual protective tools, consisting of safety glasses, ear security, and dust masks. Proper clothing is vital; loosened garments and jewelry must be avoided to avoid complicationPrior to starting any kind of equipment, operators should acquaint themselves with the devices's manual and safety functions, including emergency shut-off buttons. It is suggested to keep work spaces neat to reduce the danger of journeys and falls.

Furthermore, keeping a secure distance from relocating components is critical, and individuals should verify that all guards and safety and security tools are in place before operating the equipment. Lastly, it is essential to stay concentrated and stay clear of disturbances while working, as complacency can result in accidents. By complying with these safety tips, woodworkers can enhance their projects while minimizing threats related to equipment use.

Upkeep and Take Care Of Your Woodworking Tools

Normal maintenance and treatment of woodworking devices are necessary for guaranteeing their long life and top efficiency. Individuals should consistently clean their devices to avoid dirt and material accumulation, which can hinder performance. Consistently checking blades and bits for wear and developing them as required will enhance cutting accuracy and performance.Lubrication of moving components is essential; applying proper oils or greases protects against corrosion and keeps smooth operation. Furthermore, keeping devices in a completely dry, temperature-controlled environment shields them from wetness and extreme problems.

For power devices, checking electric connections and cords is vital to stay clear of dangers. Rotary Claming System. Developing a maintenance schedule can help woodworkers monitor necessary jobs, making sure devices stay in prime condition

Frequently Asked Questions

What Is the very best Timber Type for Beginners to Make use of?

Pine is often thought about the best wood kind for novices as a result of its softness, ease of handling, and affordability. It permits novice woodworkers to practice strategies Wood Glue Applicators without the stress of dealing with tougher, a lot more pricey timbers.

Just How Can I Boost My Woodworking Skills Rapidly?

To boost woodworking skills promptly, one ought to practice routinely, look for feedback, study techniques via publications or online video clips, and sign up with regional workshops or clubs for hands-on experience and advice from more experienced artisans.What Jobs Can I Complete With Standard Woodworking Devices?

With standard woodworking tools, one can finish projects such as straightforward furniture, birdhouses, photo structures, shelves, and reducing boards. These tasks improve skills while offering functional things for home usage or thoughtful gifts.

Are There Any Type Of Woodworking Communities for Newbies to Join?

Different woodworking neighborhoods exist for novices, including on the internet forums, social media groups, and neighborhood clubs. These systems supply support, suggestions, and chances to share tasks, fostering a sense of friendship among ambitious woodworkers.How Can I Find Reputable Woodworking Tools Assesses Online?

To locate trustworthy woodworking equipment assesses online, one can explore specialized woodworking online forums, reputable item evaluation internet sites, and social networks teams where experienced woodworkers share recommendations and insights based on their firsthand experiences with different devices.The domain name of woodworking equipment uses a huge selection of devices developed to boost both precision and imagination. When starting on a woodworking trip, novices should prioritize important equipment that simplifies the crafting process. Choosing the ideal woodworking tools requires careful evaluation of vital functions that boost functionality and efficiency. Routine upkeep and care of woodworking devices are vital for guaranteeing their longevity and optimal efficiency. With fundamental woodworking devices, one can finish tasks such as basic furniture, birdhouses, image frames, racks, and reducing boards.

Report this wiki page